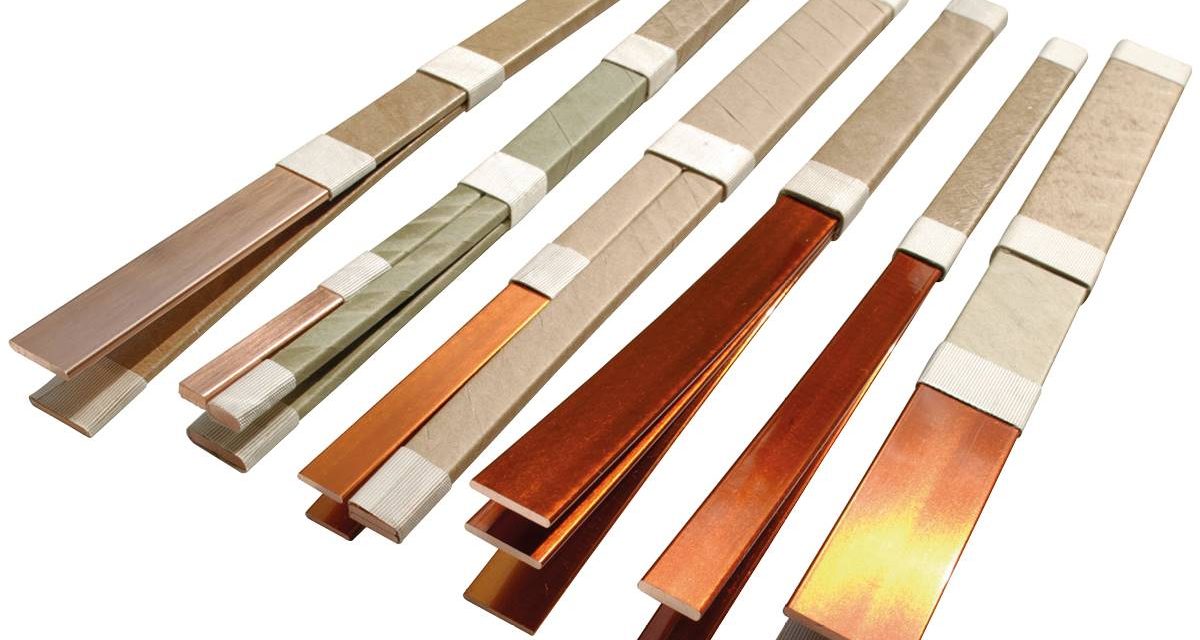

Necessary controls are made at every stage of the production of enameled coil wires produced with modern machines and the product quality is kept under constant control.

Necessary controls are made at every stage of the production of enameled coil wires produced with modern machines and the product quality is kept under constant control.

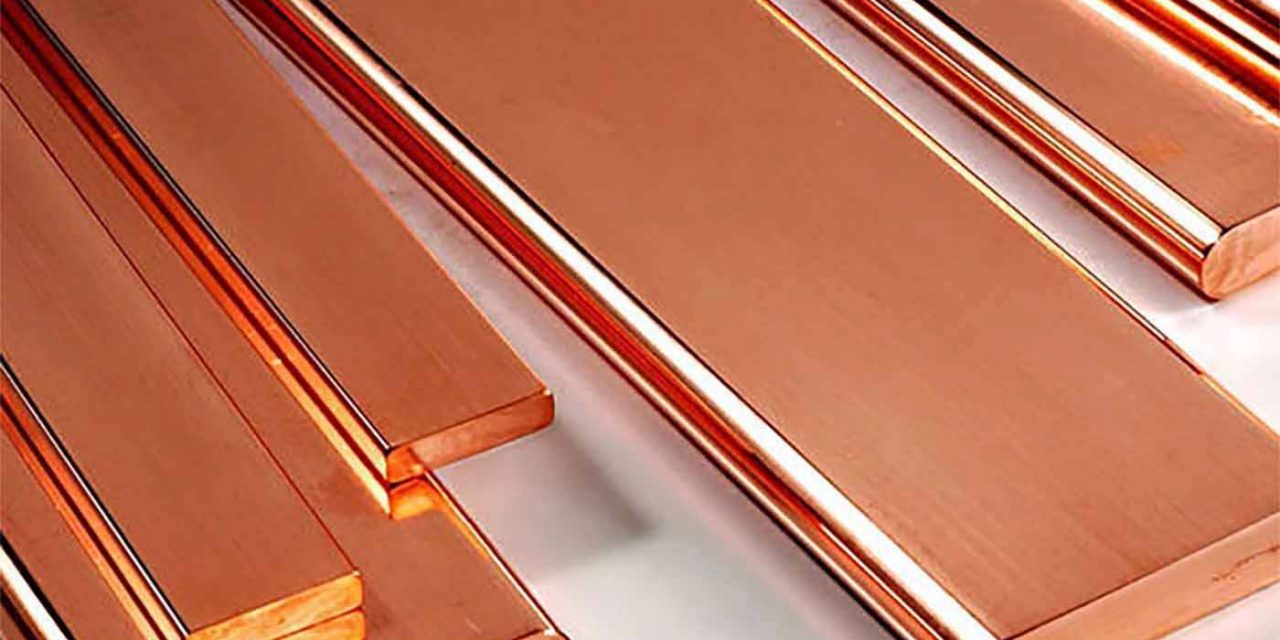

HES Cable, which produces aluminum wire rod and steel cores used in the production of overhead line conductors in its own facilities, also reflects its 40 years of knowledge and experience in the cable industry to aluminum conductors. Aluminum conductors, which are produced in fully integrated factories, are followed by an expert team from the first to the last stage of production and their compliance with the standards is professionally tested.

Attracting attention with their quality and safe structure, aluminum conductors are packaged and presented to the customer ready for use if they pass the tests successfully.

The energy produced in hydroelectric, natural gas and other power plants is transmitted to distribution centers via overhead line aluminum conductors. The quality of the conductors used is of great importance in order to ensure that the transported energy is uninterrupted and the line losses are kept to a minimum.

For the production workshop, insulation, a double layer or fully closed and mechanically in environments such as constant temperature, humidity, the paper coil provides higher insulation strength.

Enameled coil wires, which are used in many fields of industry such as electric motors, electronics industry, transformers, are produced within the HEPP.